- Retour accueil

- Vous êtes ici : Blog The Pyramids of the Cold v2 The Pyramids of the Cold Section 33 • Sneferu's Red Pyramid and the accumulated ammonia

The Pyramids of the Cold Section 33 • Sneferu's Red Pyramid and the accumulated ammonia

Publié par Bruno Coursol dans The Pyramids of the Cold v2 le 13/05/2023 à 18:48

The Red Pyramid at Dashur, built by pharaoh Sneferu (Fourth Dynasty, just before the Great Pyramid of Giza was built), showing the so-called "burial chamber", even if every single characteristic of the chamber is pointing to the exact design of a limestone kiln: the concentric layout of burnt stones and the little access to the bottom of the kiln (not visible on this particular image). Of course, just like for the Great Pyramid, the limestone kiln was only in operation in an unfinished Red Pyramid, for some period of time, before the entire structure as we know it today could be achieved.

During this operating period, the "Red Pyramid" would have looked like just any other mastaba.

The Pyramids of the Cold v2 (May 2023) • Part H: the cold production in the ancient Egyptian Great Pyramids

Section 33 • Sneferu's Red Pyramid and the accumulated ammonia in the so-called "burial chamber"

In summary: if pharaoh Sneferu did built 3 pyramids by himself, it is certainly not because of a series of mistakes or change of thoughts. At the time of their construction, the greats pyramids of Sneferu and Khufu were the biggest structures of all times, and they were designed for the exact same purpose than the modern biggest structures of our time : chemical manufacturing.

The very strong ammonia smell and the very particular layout of the "burial chamber" are telling us that the Red Pyramid was designed to manufacture sodium carbonate (the purest mineral form of natron) and sodium bicarbonate, using a Solvay-like ammonia-soda process.

33.01 The typical sodium carbonate plant design in the 1800s (Europe)

It seems that the Meidum Pyramid was a test mockup of the Red Pyramid, where each part could have been tested separately before putting everything together and build a fully functional Red Pyramid.

Actually, the global layout of the Red Pyramid is surprisingly nearly identical to a European sodium carbonate plant in the early 1800s and based on the late 1700s work by the French chemist Nicolas Leblanc. Sodium carbonate is the modern term for natron, the mummification salt used by ancient Egyptians.

For more details about the copy-paste similarities between the Red Pyramid and the 1800s typical sodium carbonate plants in Europe, please visit: http://www.verre-histoire.org/colloques/innovations/pages/p302_01_chopinet.html

In this article, drawings from Figuier are very interesting, because they show the similar layout of the Red pyramid and the 1800s European plants for natron production: 3 adjoining and successive chambers, connected by low ceiling corridors and ended by an exhaust conduct.

But the author also points out that in Europe, the industrial chemistry started with the glass industry.

And the ones who mastered the glass manufacturing process, in the first place, were the Egyptians, 5000 years ago. That is 500 years before Sneferu's reign and the Great Pyramid.

33.02 The Great Sneferu's fourth culmination pyramid at Giza

The quest of the purest natron manufacturing by Khufu's father, explains why Sneferu built 3 complete pyramids. There was no mistake or last minute change of mind, but a very modern technological development program. The Red Pyramid shows they were having difficulties in controlling the temperature of the chemical reaction units and that was the purpose of the Great Pyramid : cold production.

The Great Pyramid was the outcome of Sneferu's research program, in some way it is his fourth pyramid, and the reason this pyramid is so big, is because they had to implement a cold production unit to the initial Red Pyramid layout.

The Red Pyramid of pharaoh Sneferu, with the burial chamber and the hole supposedly digged by robbers. Photograph © Willy Blanchard, September 7, 2014: https://willyblanchard.ch/egypte-2014-pyramide-rouge/

33.03 Solvay process clue n°1: the ammonia smell of the Burial chamber

On the first photograph of the burial chamber, the blocks have also been recently covered with cement, I assume to reduce the ammonia smell. These stones would have been indirectly highly heated by the furnace of the limestone kiln, they would have get very dry, and when the operating of the Red pyramid was over, I guess all the ammonia got released in the pyramid and these dry rocks would have "sucked in" huge amount of it.

The adjoining chamber to the "burial chamber" limestone kiln, where dark traces are coming out of two opposite holes. These traces had been recently cleaned, as well as all the other traces of the wall, now hidden behind modern wooden stairs leading to the burial chamber.

The dark traces indicate that (hot) gases were injected trough these holes into structures (?) that were set into the chamber.

33.04 The over-heating problem: they couldn't cool down the towers

Because of the huge ammonia smell in the Red Pyramid, we know they didn't control the chemical reaction temperatures : the ammonia is indispensable for the Solvay process to work, but the chemical balances of the ammonia cycle, if the temperatures are efficiently controlled, give to this element a minor role: there is about the same amount of ammonia consumed than ammonia produced by the Solvay process.

If huge quantities of ammonia were produced, it is because they couldn't cool down the towers.

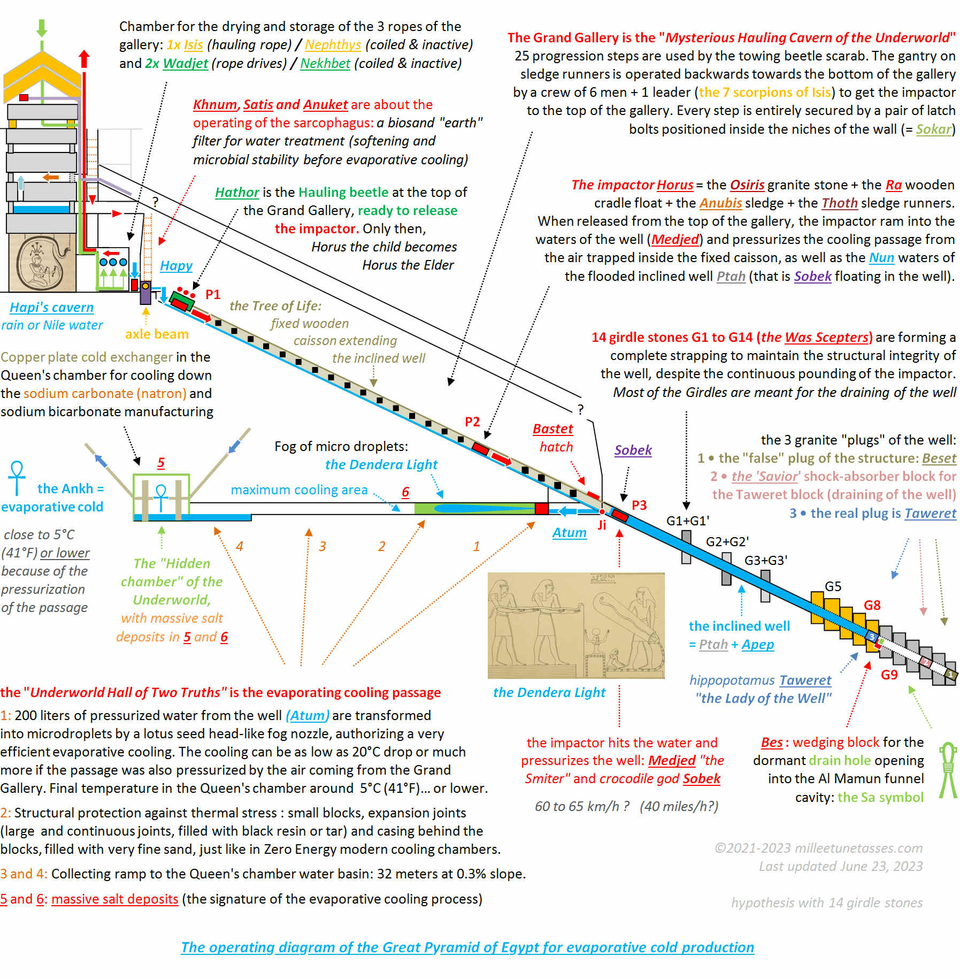

The over-heating of the reaction chambers in the Red Pyramid explains why the evaporative cold was implemented in the design of the Great Pyramid of Giza : the known part of the Great Pyramid of Khufu was designed to fix this particular problem, with the horizontal evaporative cooling passage. The cold (between 5°C and 10°C, or 41°F to 50°F), was stored inside the Queen's chamber and then would have been transferred to a Red Pyramid-like natron manufacturing unit, that would still stand today inside the pyramid, waiting to be discovered.

"A new survey of the upper chambers of Snefru’s pyramids at Dahshur", by Franck Monnier: http://www.egyptian-architecture.com/JAEA4/article23/JAEA4_Monnier.pdf

Lime kiln found in the area to the south of the basilica, uploaded by Angela Stellati, "During a recent excavation campaign in Egnatia (south-eastern Italy) a lime-kiln was discovered. It was totally sealed and its original load was still inside": https://www.researchgate.net/figure/Lime-kiln-found-in-the-area-to-the-south-of-the-basilica_fig3_266858112

Lime kiln, Betws yn Rhos, Abergele. Basic 'flare kiln' of uncertain date. "Commonly used for small-scale agricultural lime burning, as well as small construction projects from the Roman period until the 19th century. The kiln would have been loaded with limestone from the top, the roughly hewn blocks being placed to form an arch over the base of the kiln, leaving a void into which wood was placed to fuel the kiln", by Sue Anderson: http://www.cpat.org.uk/projects/longer/betws/betws.htm

On the left: the "burial chamber" of the Red Pyramid at Dashur, before cement has been poured on the blocks, I presume, in order to reduce the ammonia gas emissions. Image on the right: ancient limestone kiln at Betws yn Rhos, Abergele (Wales, United-Kingdom), thanks to CPAT Clwyd-Powys Archaeological Trust (in Recent projects, Llais Afon): https://cpat.org.uk/

33.05 Solvay process clue n°2: the burial chamber of the Red Pyramid was a limestone kiln

The burial chamber of the Red Pyramid was actually a limestone kiln: it explains why there is no floor, why the remaining blocks are burnt and laid out in concentric circles, why they are forming a cone shaped hole and why there is a little passage, supposedly digged by robbers.

A limestone kiln is the first step in sodium carbonate manufacturing

Please note, on the above left photograph, the burnt block on the foreground left corner. If you look attentively, you can find such burnt blocks all over the pit.

Diagrams of a limestone kiln and the ammonia-soda Solvay process.

https://classnotes.org.in/class11/chemistry/s-block-elements/sodium-carbonate/

33.06 The operating period of the pyramids

Of course, the fact that the burial chamber of the Red Pyramid was actually designed to be a limestone kiln, imply that when the kiln was in operation, the elevation of the pyramid had stopped, exactly like what we've already seen with the Great Pyramid : during the operation period, the pyramids weren't finished to build.

Here, for the Red Pyramid as well as for the Meidum Pyramid, it is even more obvious.

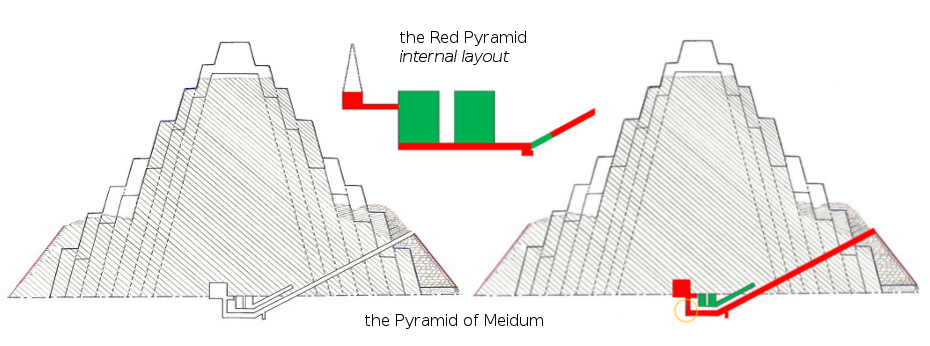

Take the Meidum Pyramid for example, and look in particular the position of the 2 separate layouts: while the chemical reaction chambers of the green layout is completely underground and their ceiling just at floor level, the "burial chamber" limestone kiln of the red layout is completely above floor level, with its floor exactly at the floor level.

What it means, is that these chambers most probably had simply been built with no pyramid around, at the exception of the supporting part on which were put the small and large "descending" passages.

In other words, ancient Egyptians did what they wanted to do on these chambers, this mock-up of the Red Pyramid, and then built the pyramid on top of it.

Left and right: the Meidum Pyramid, built by pharaoh Sneferu. Center : the Red Pyramid at Dashur, by the same king. What is remarkable in the Meidum pyramid is that it shows a perfect split of the Red Pyramid layout in 2 completely independent parts. The red layout is the energy circuit, from the limestone kiln to the exit of the pyramid. The green layout shows the 2 chemical reacting chambers and the start of the descending passage.

33.07 The 2 separate layouts of the Red Pyramid at Dashur

• The limestone kiln layout (red) for lime and CO2 production

The red layout indicates the "energy circuit", from the limestone kiln that was operated inside what is called today "the burial chamber", to the descending passage and the exit of the pyramid. Lime and CO2 were used inside the 2 chemical reaction chambers, through a Solvay-like process.

• The 2 chemical reaction chambers layout (green)

The green layout shows the 2 chemical reacting chambers and the start of the descending passage, where the natron was separated from the steam getting out of the pyramid.

The Red Pyramid is in some way, the most important of all pyramids, because it tells us what was the real goal of the 3 pyramids of Sneferu and the real function of the Great Pyramid of Khufu, his son.

On the left is the lower part of the Red Pyramid descending passage (looking up) and showing only the natural color of the stone blocks. On the right is the same passage (looking down), above the lower section, and showing red and yellow deposits both onto the ceiling and the walls.

The big pipe on the floor is going to the "burial chamber" and is supposed to bring fresh air, or get rid of most of the ammonia smell (I don't know if air is pumped in or out of the chamber).

Where the ceiling has been recently damaged, we can see the natural color of the stone. Red and yellows really are deposits, they are not the natural color of the blocks: some activity inside the pyramid, after the passage was built, was responsible for their presence.

33.08 Solvay process clue n°3: the red and yellow deposits on the Red Pyramid descending passage

On the left above photograph is the lower part of the Red Pyramid descending passage (looking up) and showing only the natural color of the stone blocks. On the right image, there is the same passage (looking down), but above the lower section, and showing red and yellow deposits both onto the ceiling and the walls.

It is very important to note that they really are deposits: where the ceiling has been recently damaged, we can see the natural color of the stone.

Red and yellow colors really are deposits, they are not the natural color of the blocks: it implicate that some sort of activity took place inside the pyramid, and after the passage was built, and that it was responsible for their presence.

The colors are not decorative paintings either: red and yellows are mingled together in such a way that no artist would have been responsible for it.

The conclusion that these colors are resulting from chemical manufacturing, is inevitable.

33.09 The Disc of Sabu responsible for these red and yellow colors?

We'll see in the next Section, that one crucial equipment for the ammonia-soda Solvay process is a dome shaped and perforated plate that allows the counterflow reactions between descending brine and ascending gas, to perform in an efficient way, and that it most probably was the real function of the Disc of Sabu.

Interestingly, the schist material in which is made the Disc of Sabu, contains a mineral with a very high concentration of iron: the ferrite. It is possible that the red deposits that are still visible inside the descending passage of the Red Pyramid (mostly on the ceiling), are coming from this ferrite mineral. The heat coming from the limestone kiln CO2 would have extract ferrite iron from discs of Sabu and it would have then deposit itself in the passage, where it would have rust and turn red.

It is still unclear to me where the yellow deposits we can also find in the passage are coming from.

Diagram of the operating Great Pyramid of Egypt for evaporative cold production (hypothetically for chemical manufacturing cooling of pure sodium carbonate "natron", the salt used for the mummification of pharaohs). When in operation, the elevation of the Great Pyramid was not finished, and it is only after the shutdown procedure and the draining of the inclined well, that the 3 granite plugs were finally close to one another.

The Pyramids of the Cold version 2 (May 2023 - March 2024)

Summary of the study and Table of Contents

Part A: The evaporative cooling process

Section 1 • The horizontal evaporative cooling passage layout

Section 2 • The Dendera Light and the creation of the fog of microdroplets by the fog nozzle

Section 3 • The water cycle glorifying metaphors: Geb, Shu, Nut, Tefnut

Section 4 • The theorization of the evaporative cooling process by Akhenaten and Nefertiti

Section 5 • The theorization of the evaporative cooling process in the Weighing of the Heart

Part B • The inclined well of the Great Pyramid of Giza

Section 6 • The inclined well layout and the girdle stones

Section 7 • The Taweret "Lady of the Well" temporary sealing granite plug of the well

Section 8 • The Bes temporary wedging block immobilizing Taweret

Section 9 • The draining of the well

Section 10 • The Great Serpent Apep and the snake water metaphors

Section 11 • The Was scepter and the control over "snakes"

Section 12 • The beating Heart of the Great Pyramid

Part C • The composite impactor of the Great Pyramid (Horus, Ra, Osiris, Medjed, Sobek...)

Section 13 • The wooden and stone composite design of the impactor: Ra and Osiris

Section 14 • The endlessly immersed Osiris stone and the seed metaphor

Section 15 • The Anubis sledge and the bobsled mask

Section 16 • The sledge runners of the impactor: Thoth

Section 17 • Medjed: the smiter nobody can ever see

Section 18 • The Apis bull and the ramming impactor's metaphors

Section 19 • The crocodile god Sobek impactor (more or less) floating in the waters of the well

Section 20 • The Obelisk and the Benben stone rising from water

Part D • The Grand Gallery's of the Great Pyramid of Giza

Section 21 • The Sacred "sloping paths" of the "oval-shaped cavern of the act of Hauling"

Section 22 • The central wooden caisson of the Gallery: Sekhmet and the Triad of Memphis

Section 23 • The hauling ropes of the Grand Gallery: Isis, Nephthys, Hatmehit, Wadjet and Nekhbet

Section 24 • The hauling Beetle and the Seven Scorpions of Isis

Section 25 • The Great Cow goddess Hathor and the operating cycle of the hauling Beetle

Section 26 • The 10 operating phases of the Grand Gallery

Section 27 • The guide to the Afterlife for the smart traveler and the canopic jars

Section 28 • The scarab amulet glorifications of the hauling Beetle

Part E • The very large and roughly finished sarcophagus of the Great Pyramid

Section 29 • The biosand filter sarcophagus of the Great Pyramid

Section 30 • The Elephantine Triad deification of the biosand filter of the Great Pyramid

Section 31 • The Great Pyramid's operating flat roof and the water supply issue

Part F • Chemical manufacturing and industrial cooling before the Great Pyramid

Section 32 • The Serdab and the "Refreshment of the Gods" Step Pyramid of Djoser

Section 33 • Sneferu's Red Pyramid and the accumulated ammonia

Section 34 • The Disc of Sabu and the Solvay process for pure natron manufacturing

Part G • The tremendous impact of the Great Pyramid on the whole ancient world

Section 35 • The hidden secrets of the Hermetica Emerald Tablet (around 1600 C.E.)

Section 36 • Thor and the magical Hammer in the Great Hall of Bilskirnir

Section 37 • The Churning of the waters of the Ocean of Milk (Hindu mythology)

Section 38 • The Tibetan prayer wheels and the Grand Gallery's operation

Section 39 and Conclusion • The cooling water of spitting Kebechet

Part H • Epilogue

Section 40 • The smiting Ark of the Covenant and the Ten Commandments

Section 41 • The 293 kilograms windlass Staff of Moses and Aaron... and the First Plague of Egypt: water turning into blood

Section 42 • Ezekiel's Four Egyptian pulley "Wheels within the Wheels" and the four angel ropes

Section 43 • David, Saul, two giant Goliaths, five little stones, an aeolian harp... and a weaver's beam

Section 44 • The holy water fonts and the biosand filter

Part I • The magicians of the Great Pyramid of Giza

Section 45 • The Legend of Khufu and the "magician" polymath Imhotep

Section 46 • The two magical eyes of Isis and the brilliant but painful flame of her twin sister's braids

Poster un commentaire